https://massivesci.com/articles/symbiosis-dysbiosis-art-biology-fungi-plants-vr-ecology-environment/

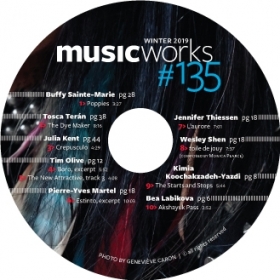

The artists in the Winter 2019 issue are connected through the sonic mycelium of Musicworks! Order the Winter issue now.

San Francisco-born, Toronto-based multidisciplinary artist Tosca Terán is collaborating artistically with Algae, Physarum polycephalum, and mycelium, translating biodata from non-human organisms into music https://www.musicworks.ca/whats-inside-musicworks-135

Learn about mycelium’s amazing potential at the intersection of art, science, and technology.

Workshop description

Workshop description

Working with Ganoderma mycelium and hardwood substrate, this workshop will include everything you need to grow a round planter, as well as hand-sculpt a small form with living mycelium! Suggestions on how to grow other forms or grow onto various armatures (3D printed, hand-knit/crocheted) will be discussed.

We will start with an introduction and demonstration of how this bio-material works, as well as discuss mycelium: what it is, its benefits to us and our environment, companies that are working with mycelium to replace styrofoam packing materials, insulating materials, everyday objects, and leather.

Participants will learn how to transform their kitchens and closets into safe mini-mycelium Biolabs.

By the end of the workshop, participants will be able to prepare mushroom media at home for art and research. They will have learned the basics of DIY aseptic technique and will leave with a mycelium bowl and bag of mycelium infused substrate!

This is a unique workshop with very limited places, so book now not to miss out.

In the end, the handy dandy Uno (naturally) works. After hours of troubleshooting with programmers, it turned out to be board issues (Trinket Pro, Feather MO). Plants will power LED neopixel strips and neopixel rings creating a moody atmosphere for the living Mycelium, that will itself create the soundscape within the dome.

Oh yeah! All done while listening to Tangerine Dream 😉

Geodesic structure made of Mycelium bricks.

Geodesic structure made of Mycelium bricks.

For my Panspermia installation taking place at the Ontario Science Centre, I will be growing/constructing a geodesic dome using mycelium grown ‘bricks’. Using 3D printed Eco ‘Nodes’ and perhaps instead of 2”x4” lumber, laser cut cardboard can be used as supports (that hold the mycelium bricks in place), allowing the entire structure to be decomposed after the installation.

Inside the Mycelium dome not only will educational materials be available a large bio-sonification structure will also be growing within a terrarium that visitors may interact with sonically.

Alien Agencies Collective colleague, Professor Joel Ong will have mycelial bio-data, generative visualizations taking place within the Mycelium Martian Dome.

Moog Audio a key sponsor!  Moog Audio is generously providing all sound gear that will be used within the Mycelium Martian Dome!

Moog Audio is generously providing all sound gear that will be used within the Mycelium Martian Dome!

![]() a key sponsor! Ecovative Design is generously providing this project GIY material towards building the Mycelium Martian Dome!

a key sponsor! Ecovative Design is generously providing this project GIY material towards building the Mycelium Martian Dome!

is generously providing this project time and mycelium cultivating expertise in growing mushrooms and will also be assisting me in growing the mycelium brick forms.

is generously providing this project time and mycelium cultivating expertise in growing mushrooms and will also be assisting me in growing the mycelium brick forms.

Some inspiration:

NASA’s 3-D Printed Habitat Challenge is advancing the additive construction technology needed to create sustainable housing for deep space exploration, including the agency’s journey to Mars.

The European Space Agency is looking at Fungi Bio-composites

MoMa NY has grown a large-scale mycelium structure at its PS1 campus.

The Mycelium Martian dome

FUNGI in SPACE

It is possible to create suitable growing conditions for fungi regarding temperature, humidity and atmosphere in a space environment. An important question, however, is whether fungi are able to survive in environments with a high radiation level. Due to weak or inexistent magnetic field, the Moon and Mars are exposed to galactic cosmic

radiation (GCR), solar winds and solar particle events (SPEs). There is, however, evidence that a specific type of fungi can survive the simulated Martian conditions [10,11] and that the ionizing radiation can even enhance the growth of melanised black fungi [12,13,14]. Onofri, de Vera, Zucconi, et al proved in their Lichens and Fungi

Experiment (LIFE) that Cryomyces antarcticus and Cryomyces minteri are able to survive the simulated martian conditions aboard the Internatinal Space Station for 18 months. They found that more than 60% of the cells and rock communities did not undergo any change due to the exposure [11]. Dadachova, Bryan, Huang, et al studied melanised microorganisms, such as Cryptococcus neoformans, Wangiella dermatitidis and Cladosporium sphaerospermum and found that ionizing radiation changes the electronic properties of the organisms and enhances their growth [13]. In another study, researchers were able to provide clues how melanised black yeast Wangiella dermatitidis has adapted the ability to survive or even benefit from exposure to ionizing radiation [14]. These studies suggest that melanin pigments play a crucial role in the survival of fungi when exposed to radiation, which could mean that it is necessary to choose, either melanin containing fungal species when developing the architectural

structures for space environment, or add melanin pigments to the species which does not contain them yet.

Fungi based biomaterials could offer the following advantages over other in situ manufacturing technologies:

• Costs: Lower manufacturing and energy costs due to excluding the costs of (a) prospecting to locate and validate the accessibility of indigenous resources, (b) developing and demonstrating capabilities to extract indigenous resources and

(c) developing capabilities for processing indigenous resources to convert them to needed products

• Manufacturing: Full manufacturing loop following a cradle-to-cradle principle: the waste of another process (e.g. greenhouse) can be used as a basis for building structures, which at the end of their service period can be used biodegraded

• Mass: Light weigh, therefore easy to handle. Can be used for complex shapes

• Known to hold compressive and tension stresses. Non-flammable, waterproof, good insulation properties.

• Strength: Forms a fibrous composite with a substrate, which enhances the

material strength. Can be used for complex shapes

• Diversity of applications and products: Enables to produce a variety of different fungi based materials: from transparent films to concrete/ brick like materials

• Speed: Grows relatively fast (in general two weeks)

GROWING FUNGI STRUCTURES IN SPACE

The additive manufacturing technology is very promising technique for utilising in situ resources on the Moon and Mars. However, when using the indigenous resources, it is also important to consider the investments needed for (a) prospecting to locate and validate the accessibility of indigenous resources and (b) developing and demonstrating capabilities to extract indigenous resources, (c) developing capabilities

for processing indigenous resources to convert them to needed products, and (d) any ancillary requirements specifically dictated by use of ISRU [1]. In that case, fungi based biocomposites might offer a cost effective alternative for constructing structures in situ.

In situ manufacturing of fungi structures would require bringing seeds of specific fungi to space which then would grow into composite structures in situ. However, only a minimum amount of seeds should be brought from the Earth for the pilot structure as the seeds for the following projects would be produced in situ. The production of fungi structures could be low cost and could require only limited human assistance, eliminating therefore costly and time consuming locating, validating and extracting processes of local resources [2].

FUNGI BIOCOMPOSITES

Fungi based biocomposites are produced by combining fungal mycelium with a natural reinforcement or filler. These materials are renewable and recyclable, and are slowly starting to replace various plastics, packaging and insulating materials on Earth. The fungi based biocomposite is also being discovered by artist, designers and architects who have been successful in using these materials in many new ways [3]. Bricks and

new architectural structures have been produced with fungi [4], as well as various fungi based products [5,6,7]. The combination of 3D printing with living organisms has been studied using 3D printing techniques with organic waste, which then formed the basis for the mycelium growth. The mycelium grew through the organic waste, forming a network of interwoven roots, which then bound the material into cohesive and strong biocomposite structure [8].

REFERENCES 1. Rapp, D., 2008. Human Mission to Mars. Enabling Technologies for Exploring the Red Planet. Springer 2. Howe, A.S., Wilcox, B., McQuin, C., Townsend, J., Rieber, R., Barmatz, M., Leichty, J., 2013. Faxing Structures to the Moon: Freeform Additive Construction System (FACS). AIAA SPACE 2013 Conference and Exposition, September 10-12, 2013, San Diego, CA (link) 3. Officina Corpuscoli: 10. http://www.corpuscoli.com/ 4. MycoWorks: http://www.mycoworks.com/portfolio/mycotecture/ 5. Ecovative Design: http://www.ecovativedesign.com/ 6. Saporta, S., Yang, F., Clark, M., 2015. Design and Delivery of Structural Material Innovations. Structures Congress 2015, p. 1253-1265 7. The Living New York: http://thelivingnewyork.com/hy-fi.htm 8. Eric Klarenbeek: http://www.ericklarenbeek.com/ 9. Lelivelt, R.J.J., 2015. The mechanical possibilities of mycelium materials. Eindhoven Univeristy of Technology (link) 10. Scalzi, G., Selbmann, L., Zucconi, L., Rabbow, E., Horneck, G., Albertano, P., Onofri, S., 2012. LIFE Experiment: Isolation of Cryptoendolithic Organisms from Antarctic Colonized Sandstone Exposed to Space and Simulated Mars Conditions on the International Space Station. Origins of Life and Evolution of Biospheres 42, p. 253-262 11. Onofri, S., Vera, J.-P., de, Zucconi, L., Selbmann, L., Scalzi, G., Venkateswaran, K.J., Rabbow, E., Torre, R., de la, Horneck, G., 2015. Survival of Antarctic Cryptoendolithic Fungi in Simulated Martian Conditions On Board the International Space Station. Astrobiology 15 (12), p. 1052-1059 (link) 12. Zhdanova, N.N., Tugay, T., Dighton, J., Zheltonozhsky, V., Mcdermott, P., 2004. Ionizing radiation attracts soil fungi. Mycological Research 108 (9), p. 1089–1096 13. Dadachova, E., Bryan, R.A., Huang, X., Moadel, T., Schweitzer, A.D., Aisen, P., Nosanchuk, J.D., Casadevall, A., 2007. Ionizing Radiation Changes the Electronic Properties of Melanin and Enhances the Growth of Melanized Fungi. Plos One (5), e457 (link) 14. Robertson, K.L., Mostaghim, A., Cuomo, C.A., Soto, C.M., Lebedev, N., Bailey, R.F., Wang, Z., 2012. Adaptation of the Black Yeast Wangiella dermatitidis to Ionizing Radiation: Molecular and Cellular Mechanisms. Plos One 7 (11), e48674 (link)

I will be holding a workshop discussing and demonstrating Midi Bio-Sonification Sunday, November 18, 2018 http://www.makechangeconference.com

I will be holding a workshop discussing and demonstrating Midi Bio-Sonification Sunday, November 18, 2018 http://www.makechangeconference.com

Receive a 20% discount on your ticket into the conference using the following code: MAKERFF

Directions on how to get to TMAC can be found here> https://www.tomediaarts.org/location Hope to see you there!

Þriðjudaginn 30. október bjóða Leirlistafélag Íslands og Myndlistaskólinn í Reykjavík uppá opinn fyrirlestur þar sem listakonan Tosca Teran talar um verk sín og vinnuaðferðir.

Þriðjudaginn 30. október bjóða Leirlistafélag Íslands og Myndlistaskólinn í Reykjavík uppá opinn fyrirlestur þar sem listakonan Tosca Teran talar um verk sín og vinnuaðferðir.

Í októbermánuði hefur Tosca verið á vinnustofu leirlistafélagsins þar sem hún gerir tilraunir með leirbrennsluaðferðina Obvara. Þar notar hún íslensk hráefni til þess að búa til gerblöndu sem myndar áferð á yfirborð leirsins þegar honum er dýft heitum ofan í blönduna. Obvara, einnig þekkt sem ,,Baltic raku”, á uppruna sinn að rekja til Austur Evrópu (Hvíta-Rússland, Eistland og Lettland) á 12. öld.

Tosca vinnur einnig að spennandi vekefnum innan ,,bio-sonification” þar sem hún býr meðal annars til tónlist með örverum og blek úr sveppum.

Nánari upplýsingar um listakonuna er að finna á vefsíðu hennar – https://toscateran.com/about/

Fyrirlesturinn verður haldinn í fyrirlestrasal Myndlistaskólans, 3. hæð, þriðjudaginn 30. október klukkan 17:00-18:30.

Fyrirlesturinn fer fram á ensku og eru allir velkomnir.

—

Obvara – Ceramics – Bio-Sonification – Music – Experiments

On Tuesday October 30 an open lecture by Tosca Teran will be held at the Reykjavik School of Visual Arts in cooperation with the Icelandic Ceramics Union.

Tosca Teran, aka Nanotopia, is a Toronto based multidisciplinary artist. Born in San Francisco, California, Tosca relocated to Canada in 2001. Working with metals, computer coding, and animation since the mid-eighties, Tosca was introduced to glass as an artistic medium in 2004. Through developing bodies of work incorporating metal, glass, and electronics, Tosca has been awarded scholarships at The Corning Museum of Glass, Pilchuck Glass School and The Penland School of Crafts. Her work has been featured at SOFA New York, Culture Canada, Metalsmith Magazine, The Toronto Design Exchange, and the Memphis Metal Museum. Most recently, Tosca has been awarded residencies at Gullkistan Centre for Creativity, Nes artist residency Iceland, The Association of Icelandic Visual Artists and the Ayatana SciArt Research Program in Ottawa. Tosca founded nanopod: Hybrid Studio maker space in 2005. Continually exploring new materials and tools, Tosca started collaborating artistically with Algae, Physarum polycephalum, and Mycelium in 2016, translating biodata from non-human organisms into music.

The lecture will be held in english and is open to all.

Ecovative GIY Artist Spotlight:

https://ecovativedesign.com/blog/178

Ecovative’s interview took place during an artist residency in Iceland where I was working with (amongst other things) Ecovative’s GIY materials.

Ecovative’s interview took place during an artist residency in Iceland where I was working with (amongst other things) Ecovative’s GIY materials.

The next installation and performance I will be working with over 100 pounds of Mycelium!

The bulk of the Mycelium will be grown from more of Ecovative’s GIY material as well as the following -Edible- grow blocks from Wylie Mycologicals :

Pleurotus citrinopileatus, the golden oyster mushroom (tamogitake in Japanese)

Pleurotus citrinopileatus, the golden oyster mushroom (tamogitake in Japanese)

The super gorgeous, Pleurotus djamor, commonly known as the pink oyster mushroom.

The super gorgeous, Pleurotus djamor, commonly known as the pink oyster mushroom.

Pleurotus ostreatus, the oyster mushroom, is a common edible mushroom.

Pleurotus ostreatus, the oyster mushroom, is a common edible mushroom.

Hericium erinaceus (also called lion’s mane mushroom, monkey head mushroom,[1] bearded tooth mushroom, satyr’s beard, bearded hedgehog mushroom, pom pom mushroom, or bearded tooth fungus) is an edible and medicinal mushroom belonging to the tooth fungus group.

Hericium erinaceus (also called lion’s mane mushroom, monkey head mushroom,[1] bearded tooth mushroom, satyr’s beard, bearded hedgehog mushroom, pom pom mushroom, or bearded tooth fungus) is an edible and medicinal mushroom belonging to the tooth fungus group.

The lingzhi mushroom is a species complex that encompasses several fungal species of the genus Ganoderma, most commonly the closely related species Ganoderma lucidum, Ganoderma tsugae, and Ganoderma lingzhi. For centuries, G. lingzhi has been used in traditional Chinese medicine for its medicinal properties.

The lingzhi mushroom is a species complex that encompasses several fungal species of the genus Ganoderma, most commonly the closely related species Ganoderma lucidum, Ganoderma tsugae, and Ganoderma lingzhi. For centuries, G. lingzhi has been used in traditional Chinese medicine for its medicinal properties.

And from Fungi Perfecti (Paul Stamets!)

This fascinating variant of the Reishi mushroom (Ganoderma lucidum s.l.) produces long, tendril-like mushrooms or “antlers” that grow slowly within the sealed environment of the spawn bag that envelops it. The resulting forest of fungi can be harvested for tea, or allowed to dry as a spectacular piece of natural sculpture.

This fascinating variant of the Reishi mushroom (Ganoderma lucidum s.l.) produces long, tendril-like mushrooms or “antlers” that grow slowly within the sealed environment of the spawn bag that envelops it. The resulting forest of fungi can be harvested for tea, or allowed to dry as a spectacular piece of natural sculpture.

I intend to sculpt with all of the grow blocks and just wait to see what happens! Will the Mycelium fruit? WIll the sculptures burst out in all directions and these amazing mushrooms appear?

The other day I heard from Fungi Perfecti HQ who wrote me the following:

Meanwhile, workshops are scheduled for September working with Ecovative substrate and workshops are currently being scheduled to build your own BIO SONIFICATION MODULE! I will be teaching anyone interested how-to start collaborating with nature through Bio-Sonification! I am super excited to share these kits. The Bio-Module kits will include the circuit board, components, DIY enclosures, Arduino code and more! Keep your eyes peeled on my workshop schedules and/or subscribe to the Studio newsletter/mailing list thing.

These upcoming workshops will be taking place in nanopod’s second location called, Baba Yaga Collective. Located at 906 Queen Street West.

I would like to thank the Canada Arts Council for their generous support towards my research in renewable, bio-sculpting materials.

“Enriching the lives of Canadians by supporting a vital and diverse arts sector”

• We acknowledge the support of the Canada Council for the Arts, which last year invested $153 million to bring the arts to Canadians throughout the country.

• Nous remercions le Conseil des arts du Canada de son soutien. L’an dernier, le Conseil a investi 153 millions de dollars pour mettre de l’art dans la vie des Canadiennes et des Canadiens de tout le pays.

As well as the generous support of the Ontario Arts Council towards my further bacterial and yeast experiements:

Looking for renewable, sustainable, bio-sculpting materials.

Researching lichen, moss and Mycelium during my residency in Iceland.

Which I intend to continue when I return to Toronto.

Other materials I have been growing are Scobys, which have proven a little tricky here (in Iceland). Perhaps this is due to the ingredients I’ve used. I’ve been unable to locate a really strong Kombucha to add to a Scoby base, in order to speed up the process. Over the month of June, I managed to grow a thin Scoby. As it is drying, however, it is proving to be too thin and fragile.

Scoby stretched out to dry.

Meanwhile, the Mycelium continues to grow. Up at Nes artist residency I started a Hexagon shape, which is now fruiting!  Saturday evening I recorded the Biodata and uploaded these sounds to Soundcloud:

Saturday evening I recorded the Biodata and uploaded these sounds to Soundcloud:

It’s not the greatest mix-down, but my equipment here is limited.

Something I am anxious to get started on is Bio-filament. Last year (I think it was last year?) I participated in a 3D printer workshop at Interaccess in order to gain access to their printers. Interaccess is a membership based New Media Maker’s space in Toronto. They have a lot of tools and equipment available for use and they also offer interesting workshops. Anyways, at the time I inquired with the Tech manager there if DIY filament was allowed as I intend to experiment and explore possibilities with soil, Scoby material and Mycelium! They said YES! So, now is as good a time as any. I’ve been researching various Extruder kits and fully assembled versions available. This is the one I went with: The Felfil EVO https://felfil.com/shop/felfil-evo-assembled/

Many reasons I went with the Evo. For one this baby can travel with me! So, I can play with Algae next time I return to Iceland or a coastal town.

Many reasons I went with the Evo. For one this baby can travel with me! So, I can play with Algae next time I return to Iceland or a coastal town.

Then something amazing happened. I received an email notification from the Canada Arts Council congratulating me on receiving a grant proposal I had sent in back in February. The Canada Council Arts Abroad program, this funding will assist me moving forward. Iceland is expensive!

Then Kai Parthy founder/experimenter over at Lay Filaments said, “…send me what diameter your 3D printer uses and I will send you a bunch of GrowLay to experiement with, on the house!” WOW!

GrowLay is made for growing Mycelium, moulds, bacteria, plants onto/into 3D printed sculptures!

Now the question is: How large can I print on the UltiMaker? I plan to divide my models into sections in order to create life size renderings and I still intend to work with Ecovative’s sculpting nutrient. Which is also waiting for me to return home!

I would like to thank the Canada Arts Council for their generous support towards my research in renewable, bio-sculpting materials.

“Enriching the lives of Canadians by supporting a vital and diverse arts sector”

• We acknowledge the support of the Canada Council for the Arts, which last year invested $153 million to bring the arts to Canadians throughout the country.

• Nous remercions le Conseil des arts du Canada de son soutien. L’an dernier, le Conseil a investi 153 millions de dollars pour mettre de l’art dans la vie des Canadiennes et des Canadiens de tout le pays.

You must be logged in to post a comment.